|

| Not much left to do |

Is the layout 95% complete? 99% perhaps? I don’t know. All I know is that there’s pretty not much left to do. I sit in front of the layout and loose myself in it. Trains running or not.

As you know, in the past few days, I was very frustrated with the tipper actuation rail. So I worked on other things to take my mind off it.

The first sector plate cassette has been built. It was made from 3mm aviation modellers plywood. On reflection this might be a little too thin and I’ll build the next one from something a bit thicker.

|

| Plywood base and strip wood sleepers match the rail height on the layout perfectly |

|

| The cassette was painted grey fading into black to match the fiddle yard. This makes it less noticeable as you can see in the top picture.. |

The layout lighting is now in place. I had been very impressed with the LED strips that James Hilton uses on his projects. I bought some from Amazon. Sixteen feet in length complete with dimmer controller for $16. It is also self adhesive backed and comes with clips to fix it in place as well. I shall use those and add a few more of my own as I’m pretty certain that glue won’t stay stuck forever. A dollar a foot and I only used 10 feet. A bargain for sure. The lighting is very even. I like it a lot

|

| First fitting of the LED strip |

Hidden behind the barrels at exit offstage is the bumper to return the skip buckets to their correct position. Making this was much easier than the tipping rail. You can’t see it, which adds to the mystery.

|

| You can’t see the tipper rail, can you? In other matters, health and safety will surely have something to say about the spillage there. |

|

| There it is |

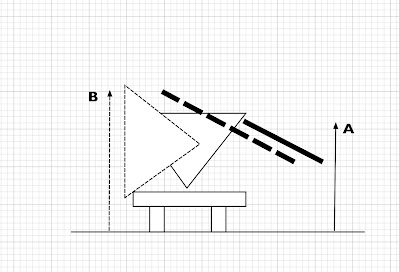

The final thing is to find a novel way to tip into the wagons at shows. Right now I just spoon a material into the skip buckets through the chute. It works. But a shows something more entertaining should be used. Something like this would be perfect. But at 1:16 scale it might be a tad too large for the area it needs to fit in. Perhaps it could be converted and adapted to fit the site in front of the sector plate.

Anyway we keep plodding along. Like any marathon I run, the finish is in sight.

.